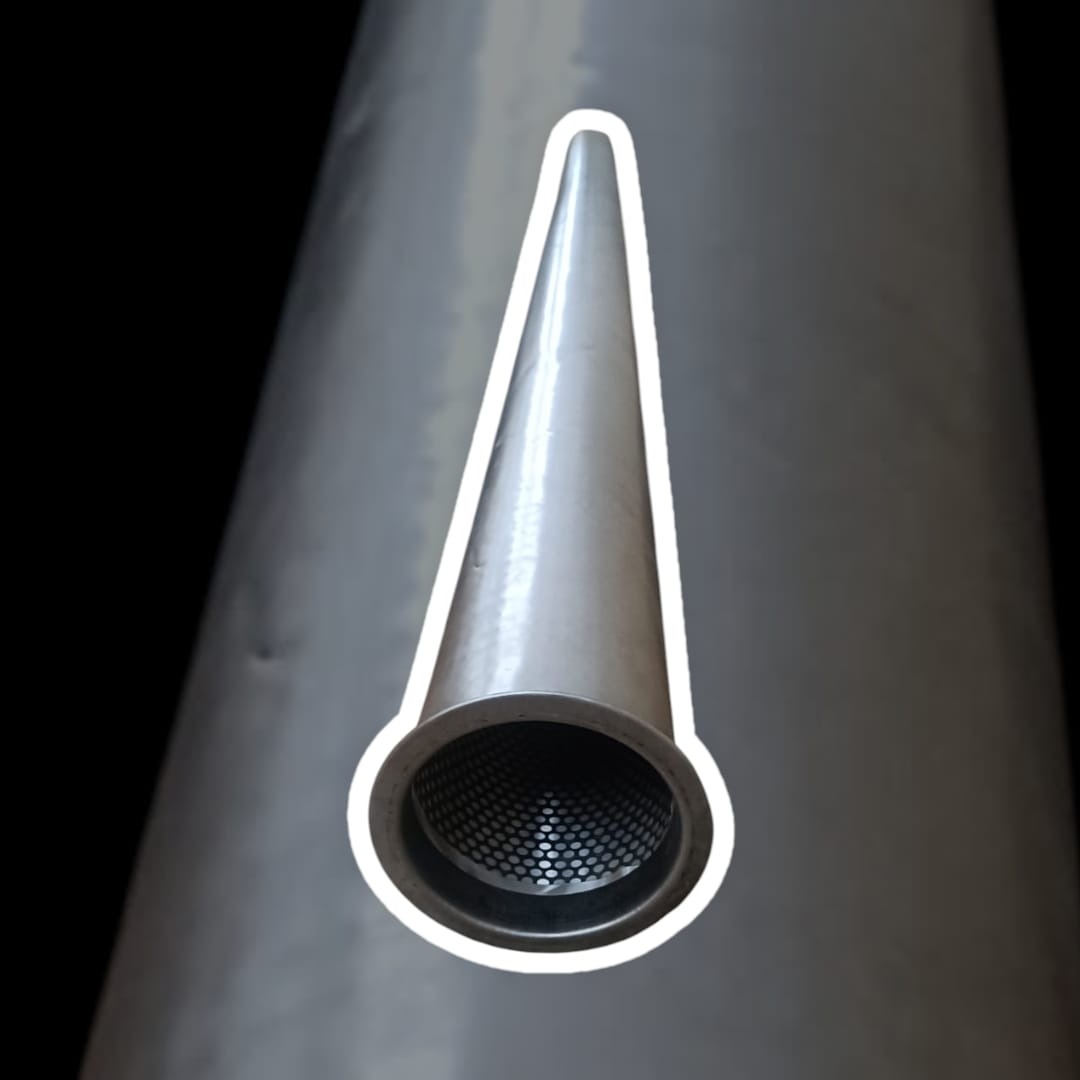

Stainless Steel Mesh Fitted Filter Cage for High Temperature

Support in High-Temperature Filtration

Prevents filter bags or media from collapsing at elevated temperatures

Maintains structural integrity under thermal stress

Hot Gas and Air Filtration

Used in baghouse dust collectors for boilers, furnaces, kilns, and incinerators

Suitable for filtering hot flue gases, exhaust air, and process gases

Protection of Filter Media

Acts as a rigid cage to protect glass fiber, PTFE, or ceramic filter media

Reduces abrasion and tearing caused by thermal expansion

Thermal Stability

Stainless steel grades (e.g., SS 304, 310, 316, 321) retain strength at high temperatures

Resistant to oxidation, scaling, and thermal fatigue

Chemical Resistance at High Temperature

Performs well in corrosive hot environments (acidic or alkaline fumes)

Common in chemical plants, power plants, and metallurgical processes

Uniform Flow at Elevated Temperatures

Mesh design ensures even gas or fluid flow, preventing hot spots

Improves filtration efficiency and system reliability

Reusability and Long Service Life

Can withstand repeated heating and cooling cycles

Lower maintenance and replacement cost compared to mild steel cages

Typical High-Temperature Applications

Boilers and power plants

Cement and steel industries

Incinerators and thermal oxidizers

Foundries and heat-treatment furnaces

Chemical reactors and dryers

Typical Temperature Capability (Approximate)

SS 304 / 316: up to ~400–500 °C(depending on environment)

Summary:

A stainless steel mesh fitted filter cage is ideal for high-temperature filtration systems because it provides mechanical support, thermal resistance, corrosion protection, and long-term durability in extreme heat conditions.