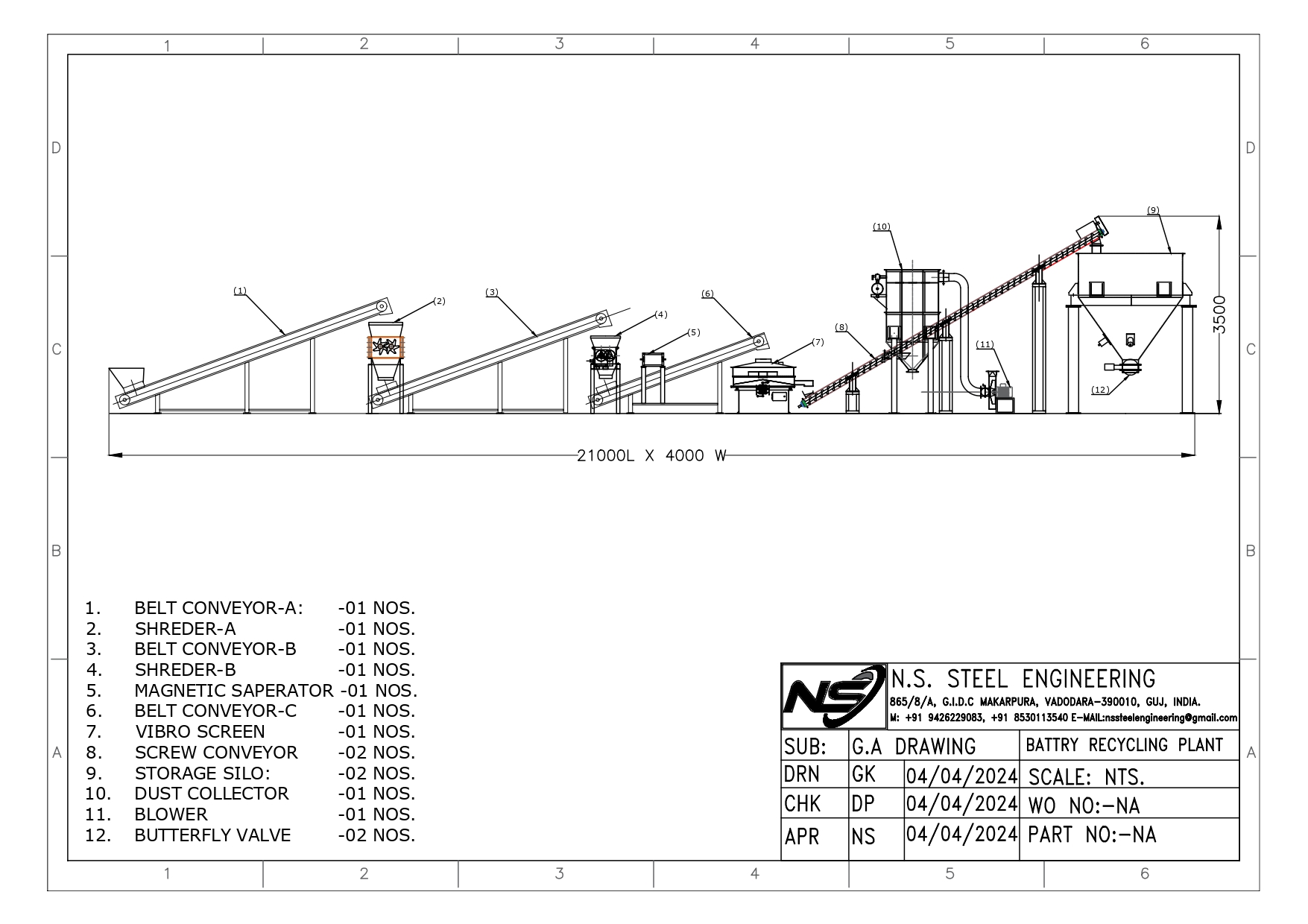

Product Description Lithium Battery Recycling Machine Introduction: Lithium-ion battery recycling machine research mainly focuses on the recovery of high-value anode metals cobalt and lithium. Copper in the negative electrode of waste lithium batteries is an important production raw material that is widely used. Toner attached to it can be used as an additive, such as plastic and rubber. According to the structural characteristics of lithium batteries, an environmentally friendly physical separation process is adopted to achieve efficient separation and recovery of waste lithium batteries. Lithium battery recycling plant is used for the disassembly and recycling of soft packaging batteries, mobile phone batteries, surgical batteries, cylindrical batteries, etc. The final products are graphite powder, lithium cobalt oxide, aluminum and copper. Lithium-ion Battery Recycling Machine Work Flow: The waste lithium-ion battery recycling machine of our company will crush the materials step by step through shredders, crushers. The whole set of equipment adopts a closed negative pressure system to reduce dust pollution, and has a pulse dust collection facilities collect dust generated during the separation process and subsequent processes. Scrap battery recycling plant Shredder A: Shredded lithium batteries into smaller pieces up to 40mm . Shredder B: For the crushed materials Below 20mm. Separation Machine: Separate the materials after being grinding size vise. Collector: Collect and release the dust. Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the whole system. Classifying Screen:Screen the materials sorted by the separation machine, and screen out of larger metal materials. Magnetic Machine: Separate nickel from the metals. High-pressure blower: Keep the whole system in a negative state so as to collect the materials and purity the air . Lithium Battery Recycling Machine Advantages: 1.High automation program, simple operation, stable performance; 2.Low power consumption, low noise, small footprint, no dust pollution; 3.Electrical separation efficiency of 99%, the finished products can be directly sold; 4.Wide range of sorting materials, sorting speed is fast; 5.No waste gas emissions, real green environmental protection sorting, no secondary pollution generation; 6.The lithium battery recycling line adopts water-cooled and air-cooled turbine mill, which makes the material separation cleaner. |Lithium Battery Recycling Machine Manufacturer In Vadodara| |Lithium Battery Recycling Machine Manufacturer In Delhi| |Lithium Battery Recycling Machine Manufacturer In Gujrat| |Lithium Battery Recycling Machine Manufacturer In India|

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.nssteelengineering.in/latest-update/product-description-lithium-battery-recycling-mach/393

Product Description Lithium Battery Recycling Mach...

2024-04-10T12:41:32

Product Description Lithium Battery Recycling Machine Introduction: Lithium-ion battery recycling machine research mainly focuses on the recovery of high-value anode metals cobalt and lithium. Copper in the negative electrode of waste lithium batteries is an important production raw material that is widely used. Toner attached to it can be used as an additive, such as plastic and rubber. According to the structural characteristics of lithium batteries, an environmentally friendly physical separation process is adopted to achieve efficient separation and recovery of waste lithium batteries. Lithium battery recycling plant is used for the disassembly and recycling of soft packaging batteries, mobile phone batteries, surgical batteries, cylindrical batteries, etc. The final products are graphite powder, lithium cobalt oxide, aluminum and copper. Lithium-ion Battery Recycling Machine Work Flow: The waste lithium-ion battery recycling machine of our company will crush the materials step by step through shredders, crushers. The whole set of equipment adopts a closed negative pressure system to reduce dust pollution, and has a pulse dust collection facilities collect dust generated during the separation process and subsequent processes. Scrap battery recycling plant Shredder A: Shredded lithium batteries into smaller pieces up to 40mm . Shredder B: For the crushed materials Below 20mm. Separation Machine: Separate the materials after being grinding size vise. Collector: Collect and release the dust. Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the whole system. Classifying Screen:Screen the materials sorted by the separation machine, and screen out of larger metal materials. Magnetic Machine: Separate nickel from the metals. High-pressure blower: Keep the whole system in a negative state so as to collect the materials and purity the air . Lithium Battery Recycling Machine Advantages: 1.High automation program, simple operation, stable performance; 2.Low power consumption, low noise, small footprint, no dust pollution; 3.Electrical separation efficiency of 99%, the finished products can be directly sold; 4.Wide range of sorting materials, sorting speed is fast; 5.No waste gas emissions, real green environmental protection sorting, no secondary pollution generation; 6.The lithium battery recycling line adopts water-cooled and air-cooled turbine mill, which makes the material separation cleaner. |Lithium Battery Recycling Machine Manufacturer In Vadodara| |Lithium Battery Recycling Machine Manufacturer In Delhi| |Lithium Battery Recycling Machine Manufacturer In Gujrat| |Lithium Battery Recycling Machine Manufacturer In India|

2024-04-10T12:41:32

Keywords

- 2.

- 1.

- set

- 20mm

- 40mm

- Delhi

- India

- Toner

- purity

- nickel

- Gujrat

- Copper

- rubber

- plastic

- company

- recovery

- crushers

- aluminum

- Vadodara

- additive

- size vise

- low noise

- shredders

- equipment

- Collector

- Shredder B

- Shredder A

- Air Cleaner

- disassembly

- Introduction

- 4.Wide range

- water-cooled

- sorting speed

- smaller pieces

- dust pollution

- final products

- negative state

- Pulse Purifier

- graphite powder

- small footprint

- Magnetic Machine

- simple operation

- sorting materials

- crushed materials

- finished products

- Separation Machine

- stable performance

- surgical batteries

- negative electrode

- Classifying Screen

- material separation

- waste gas emissions

- Product Description

- High-pressure blower

- subsequent processes

- efficient separation

- lithium cobalt oxide

- Low power consumption

- cylindrical batteries

- larger metal materials

- mobile phone batteries

- air-cooled turbine mill

- High automation program

- waste lithium batteries

- high-value anode metals

- soft packaging batteries

- structural characteristics

- Scrap battery recycling plant

- lithium battery recycling line

- secondary pollution generation

- closed negative pressure system

- Lithium battery recycling plant

- Electrical separation efficiency

- pulse dust collection facilities

- important production raw material

- waste lithium-ion battery recycling machine

- real green environmental protection sorting

- Lithium Battery Recycling Machine Advantages

- Lithium Battery Recycling Machine Manufacturer

- Lithium-ion battery recycling machine research

- Lithium-ion Battery Recycling Machine Work Flow

- environmentally friendly physical separation process

Submit Your Enquiry