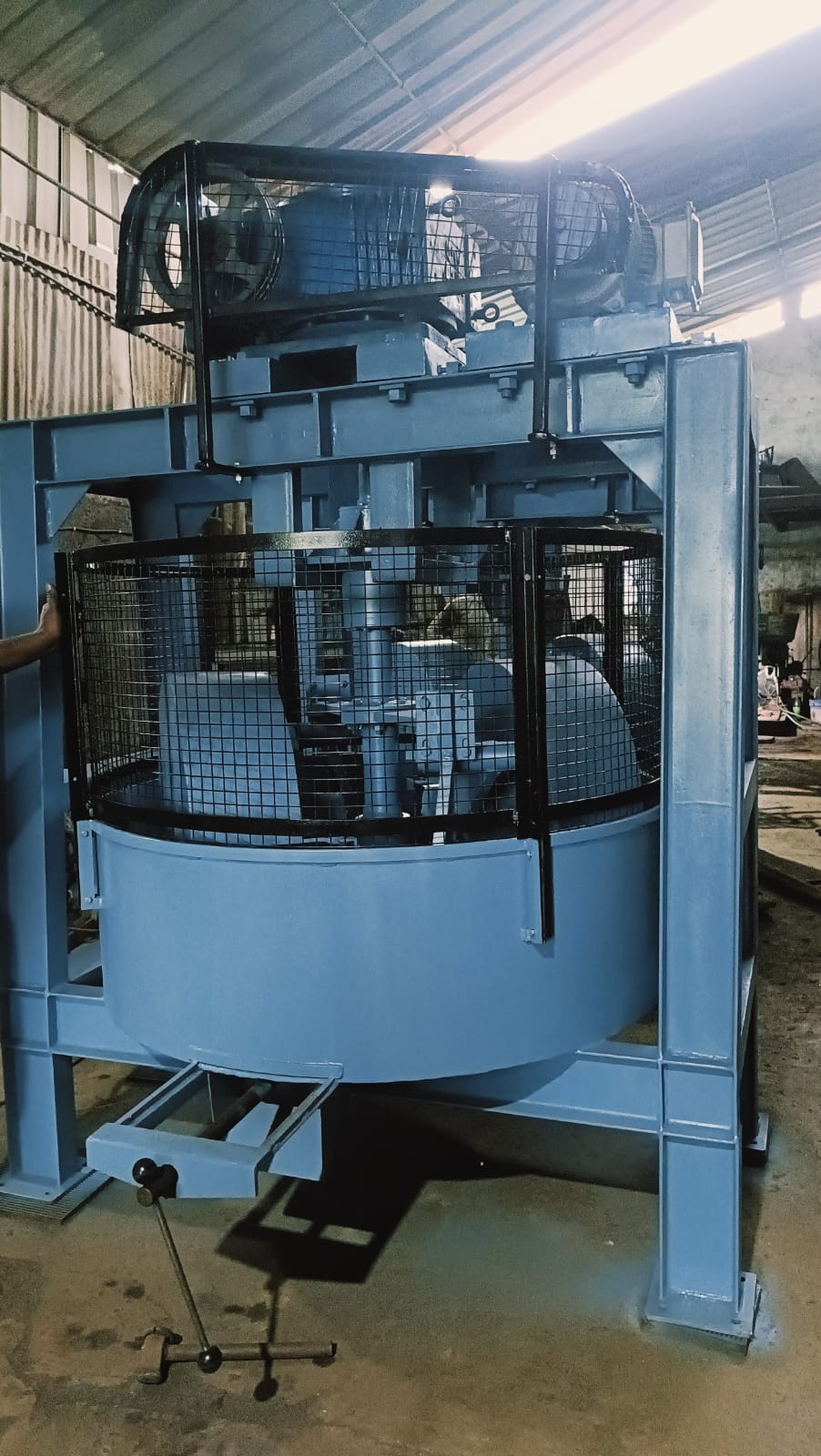

How the Muller Mixer Works Introduction: The Muller Mixer is an industrial mixing device designed to achieve uniform and thorough blending of materials. Its working principle combines mechanical agitation with controlled shear forces to ensure consistent mixing quality. **1. Components: Muller Rollers: Heavy rollers that rotate and press against the material. Mixing Chamber: The enclosed space where the mixing takes place. Drive Mechanism: Powers the rotation of the Muller rollers and other moving parts. **2. Mixing Process: Loading: Materials, such as powders, granules, or pastes, are loaded into the mixing chamber. Agitation: The Muller rollers rotate and move across the mixing chamber’s surface. This movement exerts mechanical forces on the materials, effectively blending them together. Pressing and Shearing: The rollers apply both pressing and shearing forces to the materials. Pressing forces help to compact the material, while shearing forces ensure thorough mixing by cutting and folding the material as it moves. Continuous Movement: The rotation of the Muller rollers creates a consistent and continuous mixing action. The materials are constantly lifted, tumbled, and redistributed within the chamber, preventing clumping and ensuring even distribution of components. Discharge: Once the desired mixing is achieved, the mixed material is discharged from the chamber, typically through an outlet or discharge valve. **3. Advantages: Uniform Mixing: The combination of pressing and shearing ensures that all materials are evenly mixed, reducing the risk of inconsistencies. Versatility: Suitable for a wide range of materials, including powders, granules, and pastes. Efficiency: The design allows for efficient mixing with minimal energy consumption and maintenance. **4. Applications: The Muller Mixer is ideal for industries such as: Chemical Processing: For blending chemicals and additives. Pharmaceuticals: To mix active ingredients and excipients. Food and Beverage: For combining ingredients in recipes. Construction: For mixing raw materials like cement and aggregates. Visual Diagram: Diagram/Illustration: Include a visual representation of the Muller Mixer, highlighting the key components and their roles in the mixing process. Feel free to adjust the details based on the specific features and functions of your Muller Mixer model. Including a visual diagram or animation can also help users better understand the mixer’s operation. |Muller Mixer| |Muller Mixer Machine| |Industrial Muller Mixer| |Muller Mixer Equipment| |High-Performance Muller Mixer| |Muller Mixing Technology| |Muller Mixer Features| |Muller Mixer Applications| |Muller Mixer Specifications| |Muller Mixer Benefits| |Muller Mixer Reviews| |Muller Mixer for Powder Mixing| |Muller Mixer for Industrial Use| |Long-Tail Keywords:| |Best Muller Mixer for Chemical Processing| |Reliable Muller Mixer for Pharmaceuticals| |Affordable Muller Mixer for Food Industry| |Durable Muller Mixer for Construction Materials| |How Muller Mixer Works| |Advantages of Muller Mixer Technology| |Muller Mixer Maintenance Tips| |Muller Mixer Buying Guide| |Custom Muller Mixer Solutions| |Industrial Mixing Solutions| |Powder Blending Equipment| |Granule Mixing Machine| |Paste Mixing Equipment| |Efficient Mixing Machinery|

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

How the Muller Mixer Works Introduction: The M...

2024-08-08T13:00:22

How the Muller Mixer Works Introduction: The Muller Mixer is an industrial mixing device designed to achieve uniform and thorough blending of materials. Its working principle combines mechanical agitation with controlled shear forces to ensure consistent mixing quality. **1. Components: Muller Rollers: Heavy rollers that rotate and press against the material. Mixing Chamber: The enclosed space where the mixing takes place. Drive Mechanism: Powers the rotation of the Muller rollers and other moving parts. **2. Mixing Process: Loading: Materials, such as powders, granules, or pastes, are loaded into the mixing chamber. Agitation: The Muller rollers rotate and move across the mixing chamber’s surface. This movement exerts mechanical forces on the materials, effectively blending them together. Pressing and Shearing: The rollers apply both pressing and shearing forces to the materials. Pressing forces help to compact the material, while shearing forces ensure thorough mixing by cutting and folding the material as it moves. Continuous Movement: The rotation of the Muller rollers creates a consistent and continuous mixing action. The materials are constantly lifted, tumbled, and redistributed within the chamber, preventing clumping and ensuring even distribution of components. Discharge: Once the desired mixing is achieved, the mixed material is discharged from the chamber, typically through an outlet or discharge valve. **3. Advantages: Uniform Mixing: The combination of pressing and shearing ensures that all materials are evenly mixed, reducing the risk of inconsistencies. Versatility: Suitable for a wide range of materials, including powders, granules, and pastes. Efficiency: The design allows for efficient mixing with minimal energy consumption and maintenance. **4. Applications: The Muller Mixer is ideal for industries such as: Chemical Processing: For blending chemicals and additives. Pharmaceuticals: To mix active ingredients and excipients. Food and Beverage: For combining ingredients in recipes. Construction: For mixing raw materials like cement and aggregates. Visual Diagram: Diagram/Illustration: Include a visual representation of the Muller Mixer, highlighting the key components and their roles in the mixing process. Feel free to adjust the details based on the specific features and functions of your Muller Mixer model. Including a visual diagram or animation can also help users better understand the mixer’s operation. |Muller Mixer| |Muller Mixer Machine| |Industrial Muller Mixer| |Muller Mixer Equipment| |High-Performance Muller Mixer| |Muller Mixing Technology| |Muller Mixer Features| |Muller Mixer Applications| |Muller Mixer Specifications| |Muller Mixer Benefits| |Muller Mixer Reviews| |Muller Mixer for Powder Mixing| |Muller Mixer for Industrial Use| |Long-Tail Keywords:| |Best Muller Mixer for Chemical Processing| |Reliable Muller Mixer for Pharmaceuticals| |Affordable Muller Mixer for Food Industry| |Durable Muller Mixer for Construction Materials| |How Muller Mixer Works| |Advantages of Muller Mixer Technology| |Muller Mixer Maintenance Tips| |Muller Mixer Buying Guide| |Custom Muller Mixer Solutions| |Industrial Mixing Solutions| |Powder Blending Equipment| |Granule Mixing Machine| |Paste Mixing Equipment| |Efficient Mixing Machinery|

2024-08-08T13:00:22

Keywords

- wide range

- raw materials

- Food Industry

- Heavy rollers

- Powder Mixing

- mixed material

- key components

- Uniform Mixing

- Mixing Chamber

- Visual Diagram

- desired mixing

- Mixing Process

- Industrial Use

- Pressing forces

- discharge valve

- shearing forces

- Drive Mechanism

- thorough mixing

- The Muller Mixer

- working principle

- mechanical forces

- specific features

- thorough blending

- Best Muller Mixer

- active ingredients

- Long-Tail Keywords

- The Muller rollers

- Muller Mixer model

- other moving parts

- Chemical Processing

- Continuous Movement

- mechanical agitation

- Durable Muller Mixer

- Muller Mixer Reviews

- Muller Mixer Machine

- visual representation

- Muller Mixer Features

- Reliable Muller Mixer

- Muller Mixer Benefits

- Construction Materials

- Paste Mixing Equipment

- Granule Mixing Machine

- Muller Mixer Equipment

- controlled shear forces

- Industrial Muller Mixer

- Muller Mixer Technology

- Affordable Muller Mixer

- continuous mixing action

- industrial mixing device

- Muller Mixing Technology

- consistent mixing quality

- Muller Mixer Applications

- Powder Blending Equipment

- Muller Mixer Buying Guide

- Efficient Mixing Machinery

- minimal energy consumption

- Industrial Mixing Solutions

- Muller Mixer Specifications

- High-Performance Muller Mixer

- Muller Mixer Maintenance Tips

- Custom Muller Mixer Solutions

Submit Your Enquiry